Comprehensive Testing Solutions from a Leading Materials Test Lab

Wiki Article

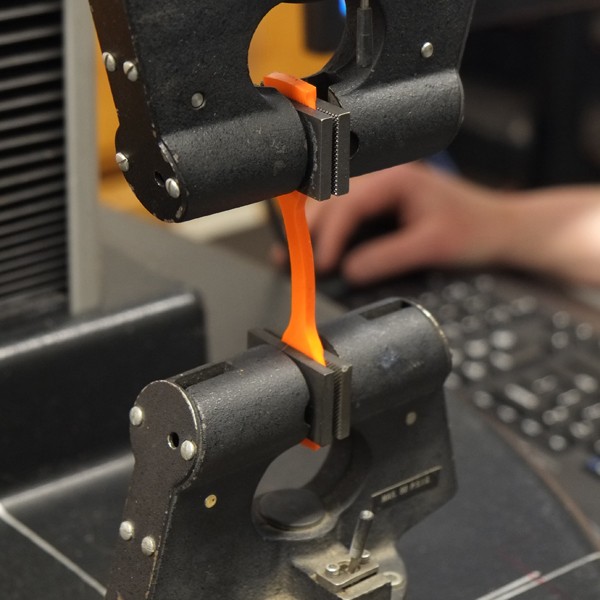

Accuracy Testing of Products for Stamina and Sturdiness

Precision screening of products for strength and longevity plays a critical function in various industries, including building and construction, production, and design. This process entails subjecting different materials to strenuous assessments to establish their ability to hold up against external forces and keep their honesty gradually.In the world of products testing, precision is critical. Engineers and researchers depend on trustworthy and exact data to make informed choices concerning material selection, design optimization, and item performance. By using advanced screening techniques and modern equipment, professionals can examine the strength and resilience of a vast array of materials, such as metals, polymers, compounds, and porcelains.

This introduction will certainly give understandings into the significance of precision screening, the kinds of products commonly subjected to testing, the key specifications for strength assessment, and the methods used for durability assessment. It will also highlight the applications and advantages of carrying out accuracy testing in various markets.

Significance of Precision Screening

Precision screening is an important step in assessing the toughness and resilience of products, offering reputable and accurate information for educated decision-making. The top quality and performance of materials play an essential duty in guaranteeing the safety and durability of frameworks and products when it comes to production and building and construction industries. Carrying out precision testing is of utmost relevance to determine whether the materials fulfill the required requirements and specifications.By subjecting materials to rigorous screening treatments, designers and suppliers can analyze their mechanical properties, such as tensile stamina, hardness, and effect resistance. This information permits them to guarantee that the products can stand up to applied pressures and ecological problems without failure or destruction gradually. Furthermore, precision screening helps determine any kind of prospective problems or weaknesses in the materials, allowing producers to make necessary renovations or adjustments to enhance performance and dependability.

In addition, accuracy screening provides quantifiable and unbiased information that can be used to contrast different materials and make informed decisions regarding their suitability for certain applications. When selecting products for important parts or structures where failure could have extreme effects., this info is specifically important.

Kinds Of Materials Subjected to Examining

Different materials go through testing for strength and toughness. This screening is essential to make sure that the products can hold up against the demands of their desired applications and to establish their anticipated life expectancy. The sorts of products subjected to screening are diverse and include metals, polymers, ceramics, compounds, and building and construction products.Metals, such as steel and aluminum, are commonly tested for their tensile stamina, firmness, and resistance to rust. materials test lab. These examinations help determine their viability for usage in architectural applications, equipment, and various commercial procedures

Ceramic products, such as porcelain and ceramic floor tiles, are tested for their compressive stamina, warmth resistance, and toughness. These tests make certain that porcelains can stand up to severe environments and high temperatures, making them appropriate for applications in the building and construction, electrical, and aerospace markets.

Compounds, which are products made from a combination of different components, are subjected to different examinations to examine their mechanical properties, such as strength, effect, and rigidity resistance. Composite materials are widely used in industries such as aerospace, auto, and sports equipment production.

you can try this out Construction products, including timber, concrete, and asphalt, undergo testing to determine their load-bearing capacity, durability, and resistance to weathering. These tests are critical in making certain the security and durability of bridges, roadways, and frameworks.

Key Criteria for Strength Examination

Materials based on testing for strength and resilience have to be assessed based upon key specifications that properly analyze their capacity to stand up to environmental problems and external forces. These specifications play an important role in figuring out the overall performance and integrity of a product. One of the key criteria for stamina analysis is the tensile toughness, which gauges a product's capacity to stand up to drawing pressures without damaging or flawing. One more vital specification is the compressive stamina, which examines a product's resistance to squashing or being pressed with each other. Furthermore, the flexural strength is significant, as it gauges a product's ability to endure bending or turning forces. The impact stamina is vital in assessing a product's resistance to sudden, dynamic pressures. Other criteria that add to stamina assessment include shear stamina, fatigue strength, and solidity. Shear strength determines a material's capacity to resist pressures that create sliding or tearing apart. Exhaustion stamina assesses a product's resistance to repeated loading and unloading cycles. Hardness is essential as it gauges a material's resistance to indentation or abrasion. By reviewing these key criteria, researchers and designers can accurately examine the strength and toughness of materials, allowing them to make informed choices in different markets such as aerospace, auto, building and construction, and production.

Techniques for Longevity Analysis

Durability assessment techniques are crucial for examining the long-lasting performance and integrity of products. These methods are essential in determining the capacity of products to endure different ecological problems and mechanical stress and anxieties over expanded periods of time. One typically used method is sped up aging, which involves subjecting materials to increased ecological conditions such as heats, humidity, and UV radiation. This enables scientists to simulate the impacts of long-lasting direct exposure in a much shorter duration, allowing them to evaluate product degradation and forecast its performance in time.One more method is cyclic testing, which includes subjecting products to duplicated loading and dumping cycles. This aids review the product's tiredness resistance and its capability to hold up against repetitive stress without failure. By evaluating the stress-strain action of the material during cyclic screening, researchers can determine possible powerlessness and assess the product's durability.

Additionally, non-destructive screening techniques such as ultrasonic testing and infrared thermography can be utilized to assess the internal stability and detect any issues or damages in the material. These techniques offer beneficial information about the material's resilience without triggering any damages to it.

Applications and Benefits of Accuracy Testing

Accuracy screening plays a vital duty in analyzing the stamina and resilience of materials, making it possible for researchers and engineers to get precise and trusted data for evaluating their efficiency. The applications of precision testing are extensive and can be found across different markets, consisting of aerospace, auto, construction, and manufacturing.One of the crucial advantages of precision screening is its capacity to determine possible weaknesses or defects in materials. By subjecting materials you could look here to regulated and rigorous screening, any problems or vulnerabilities can be found prior to they bring about tragic failures. This allows makers to make needed enhancements or modifications to improve the overall top quality and toughness of their items.

Precision screening also helps in establishing informative post the optimum style and structure of materials. By checking different variations and setups, engineers can recognize one of the most appropriate materials for particular applications. This results in improved performance, efficiency, and cost-effectiveness in various sectors.

Additionally, accuracy screening supplies valuable information for the advancement and enhancement of products and manufacturing processes. materials test lab. It permits scientists to acquire a deeper understanding of material habits under various problems, bring about the development of brand-new products with enhanced sturdiness, toughness, and efficiency attributes

Final Thought

Finally, precision testing plays an important function in reviewing the stamina and durability of materials. By subjecting numerous kinds of products to strenuous testing, essential parameters for strength analysis can be identified. Additionally, strategies for sturdiness analysis offer useful insights into the efficiency and lifespan of products. This knowledge makes it possible for markets to make informed choices and guarantees the growth of lasting and reputable items.Precision testing is an important step in reviewing the toughness and longevity of products, supplying accurate and trusted information for notified decision-making.Different products are subjected to screening for toughness and resilience. The kinds of products subjected to screening are diverse and consist of steels, polymers, porcelains, composites, and building materials.

By assessing the stress-strain response of the material during cyclic testing, scientists can recognize potential weak factors and assess the material's sturdiness.

In conclusion, precision screening plays an important role in examining the stamina and toughness of products.

Report this wiki page